- DK

- XIAMEN

- 7-10 days

- 10000 PCS

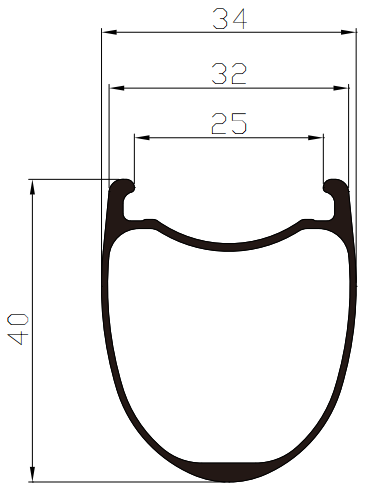

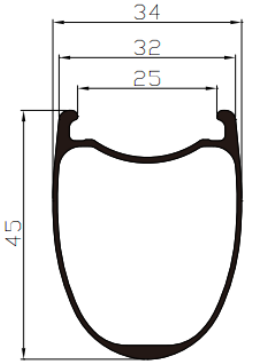

- G45TL-34

*With 32mm and 34mm outer width, designed for off-road, gravel, cyclocross bikes.

*Clincher and tubeless ready designs, compatiable for both tube tires or non tube tires.

*Asymmetric and symmetric structure designs both are available.

*Recommended tire size is 700*30C-50C.

*Wide U shape designs, better aerodynamics and stiffness.

*Wider 32/34mm designs, allow lower pressure, generates less rolling resistace on rough tracks.

*2 years quality warranty.

Ⅰ.Features:

1.With 32mm and 34mm outer width, designed for off-road, gravel, cyclocross bikes.

2.Clincher and tubeless ready designs, compatiable for both tube tires or non tube tires.

3.Asymmetric and symmetric structure designs both are available.

4.Wider 32/34mm designs, allow lower pressure, generates less rolling resistace on rough tracks.

Ⅱ.Descriptions:

| Symmetric Models | ||

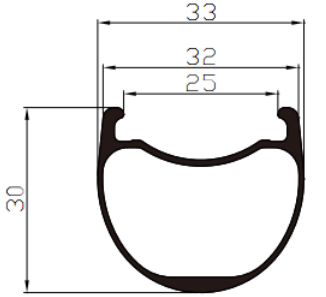

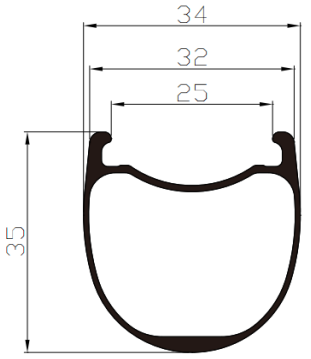

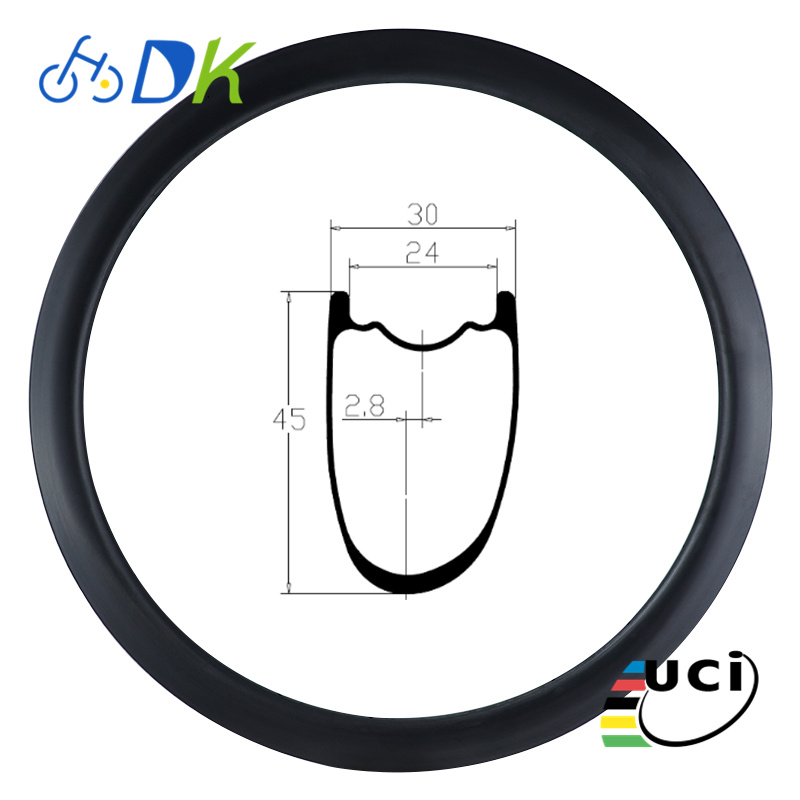

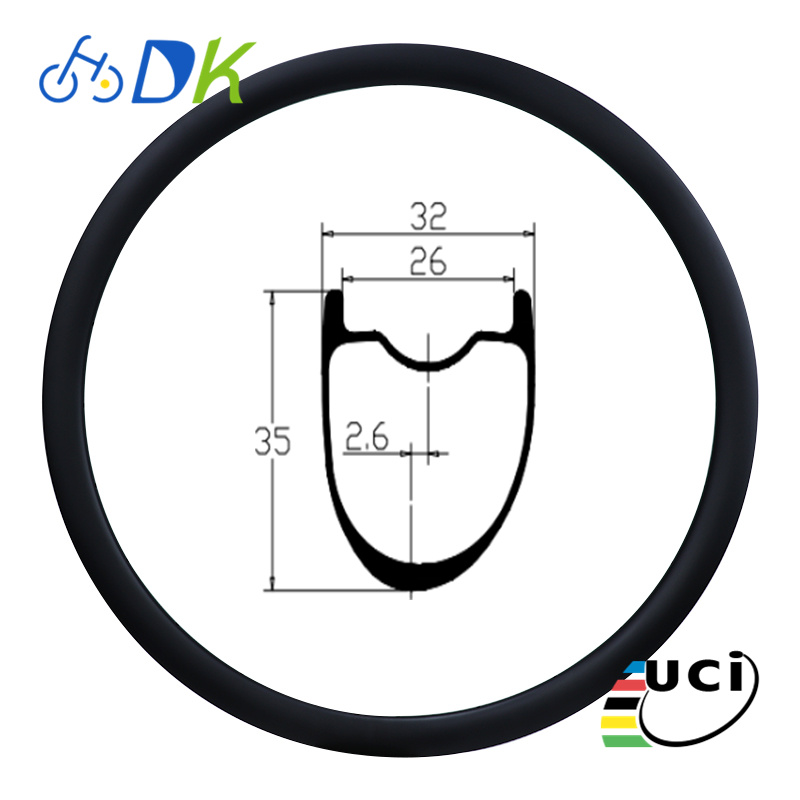

| Model: G30TL-34 | Model: G35TL-34 | Model: G40TL-34 |

|

|  |

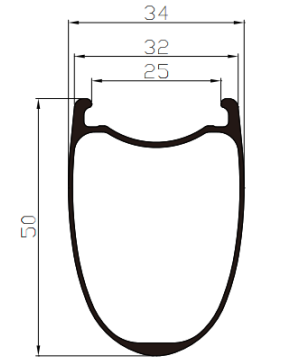

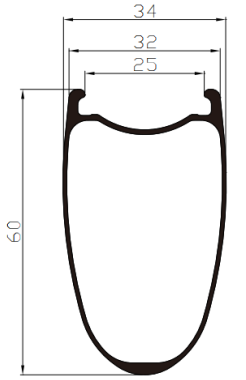

| G45TL-34 | G50TL-34 | G60TL-34 |

|

|

|

30MM Weight: 440±15g(T700) 385±15g(T800) 365±15g(T800 Paintless) | 35MM Weight: 465±15g(T700) 395±15g(T800) 375±15g(T800 Paintless) | 40MM Weight: 475±15g(T700) 410±15g(T800) 385±15g(T800 Paintless) |

45MM Weight: 485±15g(T700) 420±15g(T800) 395±15g(T800 Paintless) | 50MM Weight: 500±15g(T700) 440±15g(T800) 415±15g(T800 Paintless) | 60MM Weight: 560±15g(T700) 480±15g(T800) 460±15g(T800 Paintless) |

| 30MM Weight Limit: <100kg | 35MM Weight Limit: <110kg | 40MM Weight Limit: <115kg |

| 45MM Weight Limit: <115kg | 50MM Weight Limit: <115kg | 60MM Weight Limit: <125kg |

| 30MM ERD: 583mm | 35MM ERD: 573mm | 40MM ERD: 563mm |

| 45MM ERD: 553mm | 50MM ERD: 543mm | 60MM ERD: 523mm |

| Materials | Full Carbon Fiber, Toray T700+T800 high modulus materials | |

| Recommended Tire Size | >28C | |

| Roundness | <0.25mm | |

| Flatness | <0.15mm | |

| Max Spoke Tension | >350kgf | |

| Finish: | UD/3K/12K, Matte/Glossy | |

| Available Spoke Holes: | 16-36 Holes | |

| Warranty: | 2 years | |

Ⅲ.Photos of A Complete G45TL-34 Carbon Spoke Wheelset for Gravel, Cyclo-Cross Bikes, Weight Only 1202 Grams:

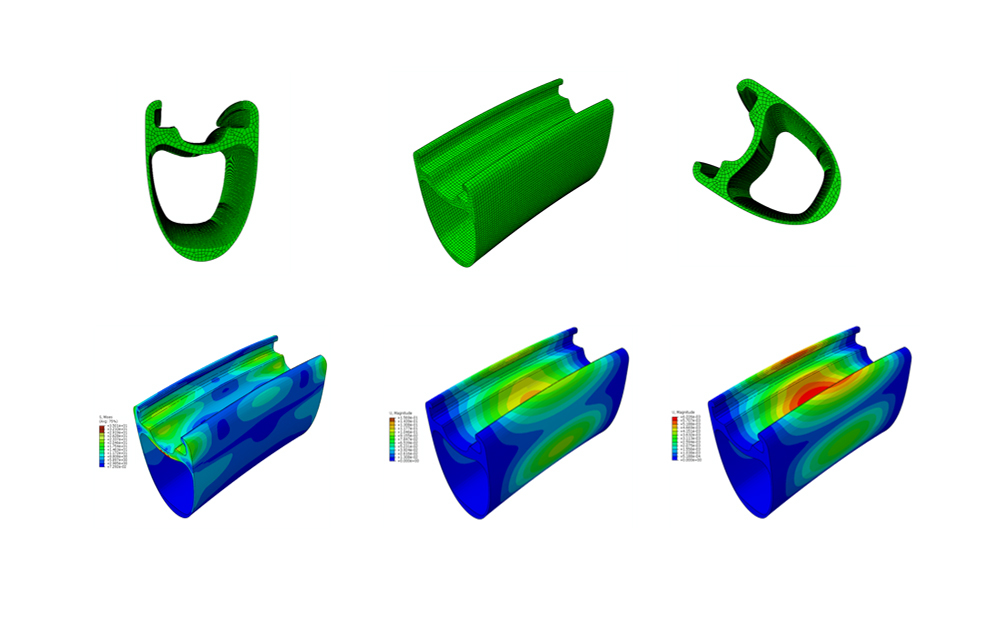

Ⅳ.FEA(Finite Element Analysis):

Ⅴ.Paintless VS Painted Finishes:

Ⅵ.Technology:

-1) Reinforcement Technology

DK Composite use reinforcement/thicker carbon fiber on each spoke hole area, and use thinner carbon fiber outside the spoke hole area, so the rim light can be saved greatly while strength can be guaranteed.

-2) Unique Resin and Lamination System

DK Composite developed own high TG 255℃ and high tenacity resin system and special lamination for best carbon bicycle rim performance.

-3)Six-Axis Drilling Machine

DK Composite developed a six-axis machine especiall for carbon bicycle rim, so all kind of angles and diameters drilling are available.

-4) Strong R&D Team

DK Composite have own R&D team for new project and mould development, except carbon bicycle rim, we also have the experiences and ability to develop any new carbon composite products.