T800/T1000 Super Light and Strong 700C Road/Gravel Rim

Ⅰ.Features:

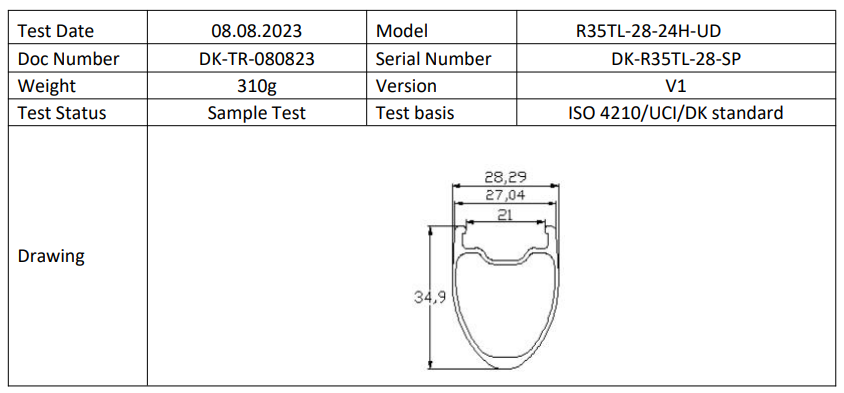

1.T800/T1000 super light 320g rim for road bike or gravel bike races.

2.The ample rim width provides a stable platform for wider gravel tires.

3.Rim had passed rigorous in-house UCI impact resistance tests of 110J of load with no cracks nor lateral/radial run-outs

4.The Flyweight version withstands the impacts of 110J. The R35TL-28 rims prove that strong and aero does not equal heavy.

5.The free paint/paintless finish is a flawless, protective surface formed during the rim molding process, eliminating the need for traditional post-production treatments.

6.The bead lock design on the center channel, allowing for the pinch flat and puncture resistance tubeless tires of your choosing.

Ⅱ.Introduction

Ⅲ.Summary:

-1)Test requirements fulfilled.

-2)All laboratory tests passed.

Ⅳ.Test Items Overview:

-1)Brake Track Flatness and Roundness Tests:

| Test Conditions | Judgement Standard | Test Results | Judgement |

| 1.Place the rim on the test turntable, with the dial indicator aligned with the middle of the brake track; 2.Rotate the rim for a circle, and record the maximum and minimum values of the dial indicator, the difference between the two is the flatness of the braking track; 3.The method of testing the roundness of the rim is the same as above. | 1.Brake track flatness ≤0.3mm; 2.The roundness of the rim is ≤0.3mm. | 1.Brake track flatness is 0.11mm; 2.The roundness of the rim is 0.15mm. | OK |

-2)Lateral Stiffness Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1. Fix the rim on the special fixture; 2. Apply 20kgf(196N) force to the valve hole, record its deformation and calculate the corresponding stiffness values; 3. Take the average values of the stiffness obtained from three different applied forces as the final rim stiffness value; 4. Measure once before and after the wheel building; 5.The built wheel is a disc brake rear wheel with stainless steel spoke, the hub axle size is 142mm, and the spoke tension on the drive side is 120±10kgf. The drive side is placed upward during the test. | 1.The stiffness value before wheel building is ≥6N/mm. 2.The stiffness after wheel building (rear wheel drive side) ≥ 30N/mm | 1.Before wheel building: 7.7N/mm 2.After wheel building: 37.4N/mm | OK |

-3)Radial Stiffness Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1. Fix the rim on the bottom plate of the universal testing machine, with the valve hole facing up; 2. Apply a force of 50kgf (490N) to the valve, record its deformation and calculate the corresponding stiffness value; 3.Take the average value of the stiffness obtained by three different applied forces as thefinal rim stiffness value. | 1. Stiffness value (rim) ≥ 100N/mm | 1.Rim stiffness: 142.2N/mm | OK |

-4)Vertical Impact Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1. Drop hammer weight: 22.5kg; 2.Drop hammer shape::cylindrical, flat bottom, bottom with silicone pad, thickness 10mm (hardness Shore A=50±5); 3. Test without tires; 4. After the wheel set is fixed, raise the drop hammer to 48J (height 217mm), release the drop hammer, let it fall freely to the outer circle of the rim, and observe whether the rim is cracked or broken. If there is no crack or break, then increase the height successively and continue the test until crack or break appears. | 1. 60J without any damage, it is determined that the test is passed. | 1. 48J, 60J, 70J, 80J, 100J, 110J are normal, 120J is broken; | OK |

-5)Spoke Hole Pull Out Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1.Fix the rim on the special fixture; 2. The rising speed of the machine head is 10mm/min; 3. Apply a force of 300kgf to the spoke holes, and test 6 different hole positions; | 1.After the tensile force reaches 300kgf, there should be no cracks and bulges in the spoke holes. | No crack or bulge | OK |

-6)Tire Pressure Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1. Pumping tool: pump; 2. Tire model: Schwable pro one 25C tubeless tire, no rim tape; 3. Tire pressure: 100psi; 4. Inflating steps (single rim without wheel building): a. Tire installation (check the difficulty of tire installation); b. Inflate (pay attention to whether it is easy to inflate, and pay attention to check the air pressure when the tire is fully in place); c. Check the deformation of the rim after inflating; d. The inspection tool checks the deformation of the braking edge; e. Water inspection (check the sealing condition of the rim); f. Tire removal (check the difficulty of tire removal). | 1. It should be easier to install and remove tires. When inflating, the tires should be fully in place at 50-100psi. After deflation, the tires should be stuck in place and cannot automatically bounce off; 2. After inflating, the rim surface must not be sunken or twisted; 3. The deformation of the brake side (superimposed on both sides) after inflating is ≤0.3mm. If the gage passes, it is OK; if the gage fails, it is NG; 4. After reaching the specified tire pressure, there is no air leakage in the water test. | OK | OK |

-7)Tire Inflatable Pressure Test

| Test Conditions | Judgement Standard | Test Results | Judgement |

1. Tire: Model PURSUER 700*25C clincher tire, inflated with an air pump; 2. When the tire pressure reaches 100psi, measure and record the deformation of the brake edge; 3. Continue to inflate to 200psi, and observe whether there is any abnormal sound during the process; 4. Return the tire pressure to 100psi, measure the deformation of the brake edge again and record it, and calculate whether there is any change in the comparison of the two measurement data before and after. | 1. When the air pressure reaches 150psi, let it stand for 5 minutes, no abnormal sound is allowed; 2. When the air pressure reaches 190psi, stand still for 5 minutes, no continuous abnormal sound or more than three short-term abnormal sounds are allowed; 3. The difference between the measured data before and after the tire pressure of 100psi should be less than 0.05mm. | OK | OK |

Ⅴ.Impact Test Video:

Ⅵ.Test Report